On the 25th February the Government confirmed that from September 2021, regular grade unleaded petrol in the UK will increase to 10% Ethanol (E10) from the current 5% (E5).

When Ethanol is burnt, it produces less emissions and therefore helps towards the Government’s targets for lowering our carbon footprint. The 5% increase in Ethanol in pump fuel has the effect of taking 350,000 cars off the road in the UK and will remove 750,000 tonnes of Carbon Dioxide from the atmosphere, thus helping to reduce global warming. Basically, Ethanol is good for modern petrol car engines that have been designed for E10.

But what does that mean for garden machinery?

In summary, while there are significant environmental benefits in switching to E10, it is not designed to be stored for long periods, so using it in garden machinery which is used infrequently is not recommended. Many manufacturers, including Husqvarna and Honda, recommend that fuels containing ethanol should be consumed within a 30-day period in order to minimise the risks of damage to your lawncare equipment.

As an alternative, Aspen is an Ethanol-free alkylate petrol, which is very pure compared to petrol so it can be left in machinery tanks for many years without degrading and will not form gummy deposits when it eventually evaporates. The emissions from regular petrol, even with the increased Ethanol levels, are still substantially more hazardous to machinery operators than those from Aspen fuels.

All Lloyd Ltd Parts Departments have stock of 1 and 5 litre containers, but larger quantities are available on request.

Read below to learn more.

E10/Ethanol – what is it?

Ethanol is a renewable source bio-fuel, which is also known as Ethyl Alcohol. It is the Alcohol that is formed when sugar is fermented in alcoholic drinks and is mostly made from Cereals, Sugar Beet, Maize or general Biomass waste. Ethanol can be mixed with unleaded petrol in various grades.

E5 = 95% unleaded petrol & 5% Ethanol. E10 = 90% unleaded petrol & 10% ethanol.

When Ethanol is burnt, it produces less emissions and therefore helps towards the Government’s targets for lowering our carbon footprint. The 5% increase in Ethanol in pump fuel has the effect of taking 350,000 cars off the road in the UK and will remove 750,000 tonnes of Carbon Dioxide from the atmosphere, thus helping to reduce global warming. Basically, Ethanol is good for modern petrol car engines that have been designed for E10.

How does E10 petrol work in garden machinery?

Just like the car industry, small engine machinery manufacturers have been preparing for the change to E10 for many years and all Euro V rated engines (2017-2021) have been emissions-certified using an E10 fuel. In theory, this means that many machines will work fine on E10 but older machinery may have fuel systems that will degrade very quickly as components have not been designed with E10 in mind.

Ethanol is a solvent and is damaging to plastic and rubber and will often leave behind gummy deposits (pictured) when the fuel evaporates. This shortens the service life of fuel system components and can cause blockages inside the carburettor causing poor running.

Ethanol reduces the storage life of petrol

Whilst using fresh E10 fuel in modern machines won’t cause problems, the same storage problems exist in new and old machines as ethanol changes the behaviour of petrol during storage.

Ethanol binds moisture and acidifies, resulting in the shelf life of the fuel deteriorating which can lead to many problems for owners who use their machinery infrequently or store them for longer periods of time.

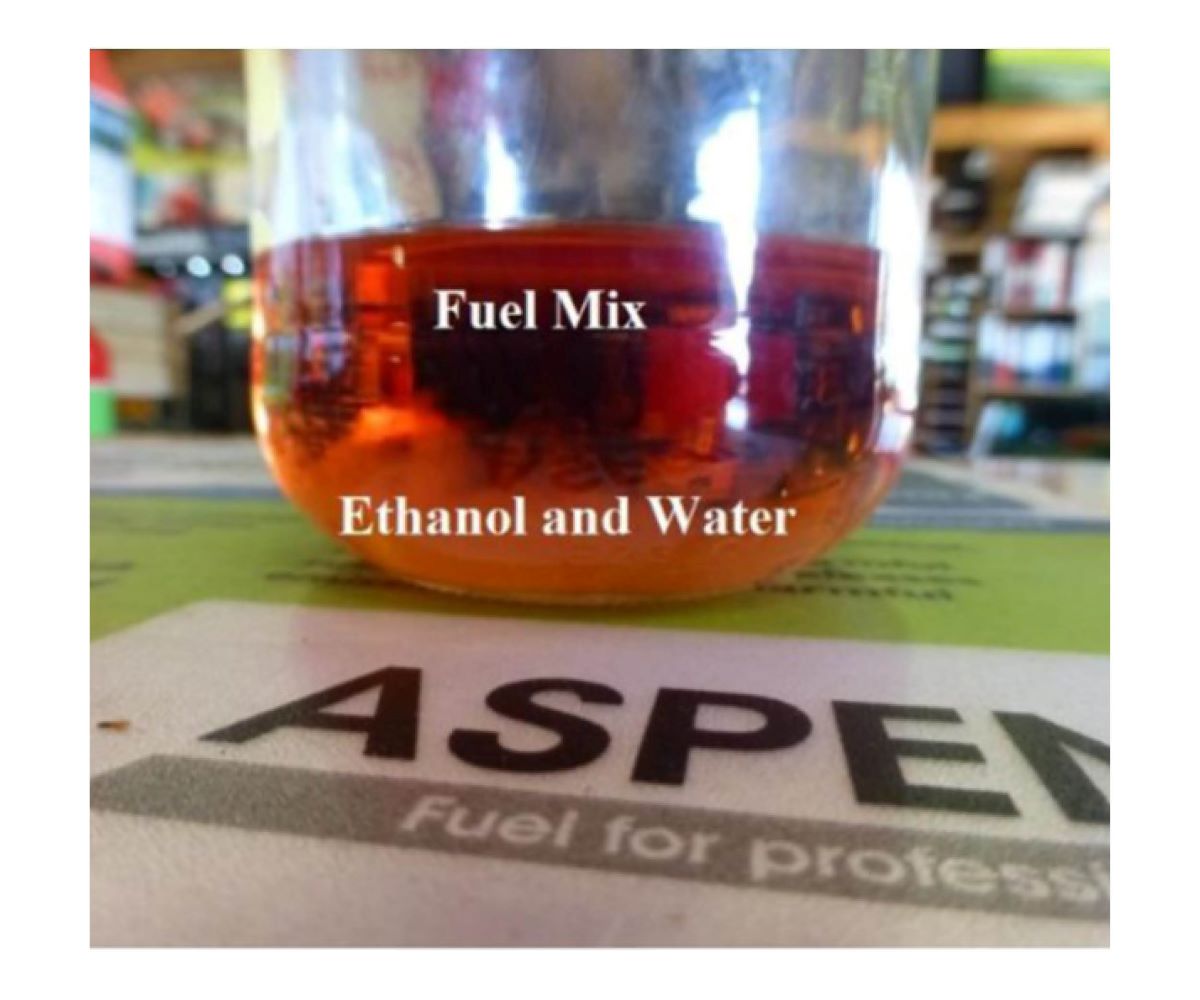

Have you ever noticed water inside of machinery fuel tanks and questioned how it got there? It is unlikely that the owner tried to fuel their machine with tap water, but Ethanol is Hygroscopic, which means it attracts and absorbs water. The fuel mix will keep the water suspended but eventually, the moisture build up becomes too high will then separate from the fuel in a process known as

phase separation.

This phase separated Ethanol and water mix is highly corrosive to aluminium, it is the cause of the white powder found in many damaged carburettors ( Aluminium Oxide). This can alter the fuel flow inside the carburettor which will contribute to poor engine performance.

Petrol floats on water, therefore in the fuel tank water is at the bottom of the tank. The fuel feed is at the bottom of the tank therefore the more water that is attracted to the fuel, the more running problems an engine will have.

Carburettors and engines affected by water/ethanol/stale fuel are unlikely to be covered by warranties.

How does using Aspen Fuels help?

ASPEN is an Ethanol free alkylate petrol, which is very pure compared to petrol. Aspen can be left in machinery tanks for many years without degrading and will not form gummy deposits when it eventually evaporates.

Although the introduction of more Ethanol into regular petrol will reduce environmental emissions, the remaining emissions are still substantially more hazardous to machinery operators than those from Aspen fuels.

What are the benefits of using Aspen Fuels?

- Aspen does not contain ethanol.

- No expensive repair bills caused by stale fuel.

- Your machine always starts and is ready to go, even after long standstill periods.

- Lasts for years without deterioration.

- Virtually odourless.

- Less maintenance and a longer machine life.

- Premixed 2-stroke means you don’t have to mix it yourself.

- Easy to select the correct fuel using the coloured cans and coloured reminder stickers on your machine.

- Protects your health and the environment.

For more information

For more about Aspen fuels, please contact your local Lloyd Ltd Parts Department or complete the form below.